Understanding Multi-Layer Rubber Membrane in Business Applications

Introduction to Multi-Layer Rubber Membranes

Multi-layer rubber membranes are innovative materials that have found their place across various industries, significantly impacting practices in fields such as health, beauty, and medical treatments. These membranes are designed to provide maximum durability, flexibility, and resistance to various environmental factors, making them an excellent choice for numerous applications. This article explores the incredible versatility of multi-layer rubber membranes, their applications, and their advantages in business.

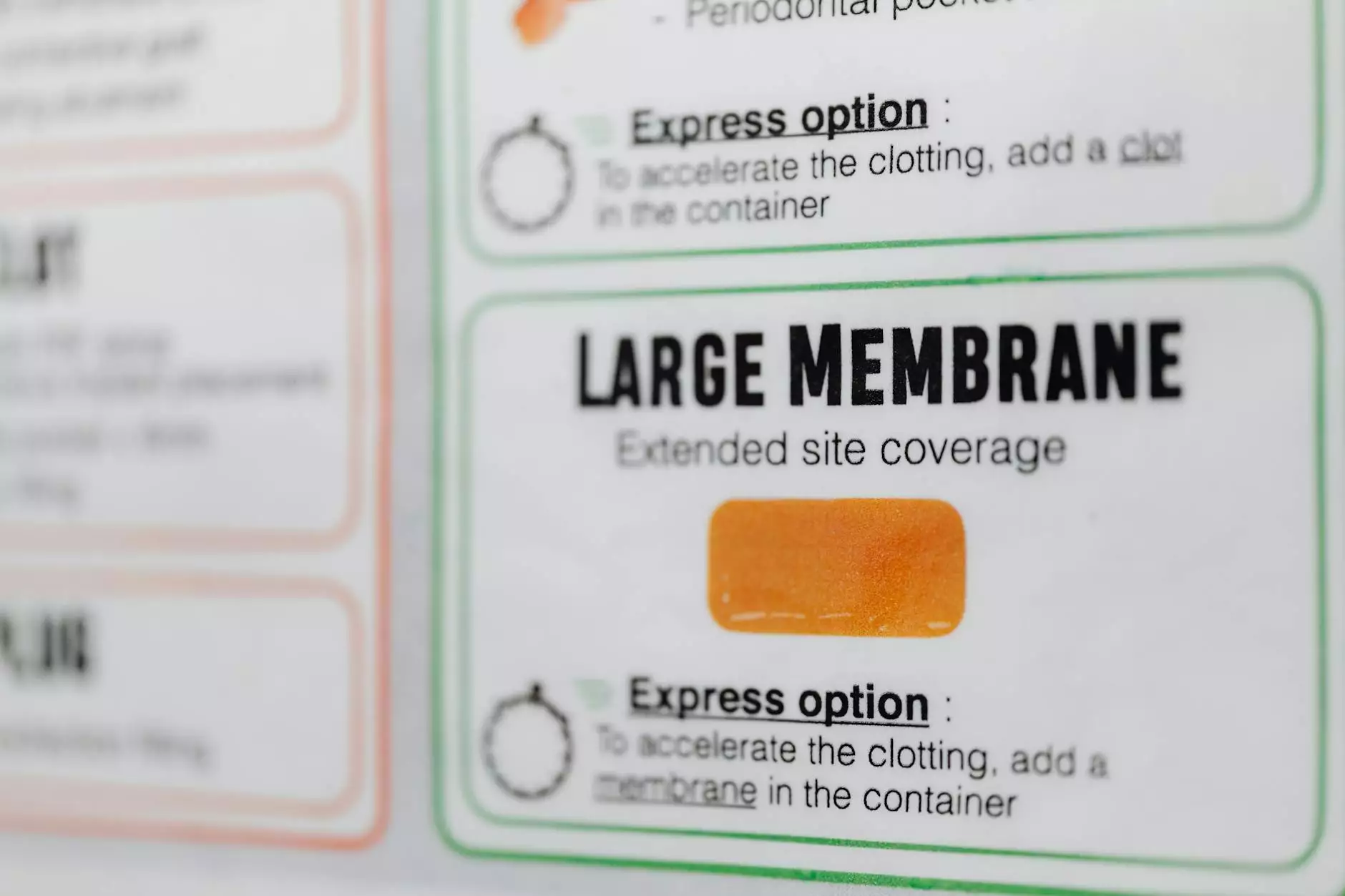

The Structure and Composition of Multi-Layer Rubber Membranes

The fundamental characteristic of a multi-layer rubber membrane is its unique construction, which consists of several layers of rubber and sometimes other materials. Each layer is designed to contribute specific properties:

- Outer layer: Provides protection against environmental factors such as UV rays, ozone, and various chemicals.

- Middle layers: Often engineered for specific functions such as moisture control, breathability, and flexibility, enhancing the overall performance.

- Inner layer: Responsible for structural integrity and may include specialized coatings to prevent sticking and to improve adhesion.

Applications in the Health Sector

In the health industry, multi-layer rubber membranes play a crucial role in various medical applications. Here are some key uses:

- Medical Devices: Essential components in the production of medical devices that require airtight and watertight seals. These membranes prevent contamination and ensure patient safety.

- Pharmaceutical Packaging: Used in packaging solutions that need robust barriers against moisture and light to preserve the efficacy of medications.

- Protective Gear: Integral to the manufacturing of high-quality personal protective equipment (PPE) that is both comfortable and protective against pathogens.

Impact on Beauty and Spa Industries

The beauty and spa industries have also embraced multi-layer rubber membranes, utilizing their unique properties in various ways:

- Facial Masks: Many cosmetic brands utilize these membranes in facial masks, providing a better fit and deeper penetration of active ingredients.

- Spa Treatments: Used in wraps and other thermal treatments, they help in maintaining temperature, enhancing the overall experience for spa-goers.

- Durable Surfaces: Spa facilities employ these membranes for flooring and surfaces, ensuring longevity and ease of maintenance.

Benefits of Multi-Layer Rubber Membranes

The use of multi-layer rubber membranes offers a myriad of benefits across industries:

- Durability: Designed to withstand wear and tear, these membranes offer a longer lifespan compared to single-layer alternatives.

- Versatility: Their adaptable properties make them suitable for a wide range of applications across different sectors.

- Cost-Effectiveness: While the initial investment might be higher, their durability and lower maintenance requirements yield significant savings over time.

- Health & Safety: Ensuring that products in contact with skin or used in medical environments meet health standards is crucial; these membranes can aid in achieving this.

Innovations Driving the Multi-Layer Rubber Membrane Market

Continuous innovation is reshaping the landscape of the multi-layer rubber membrane market. Key trends include:

- Smart Membranes: Integration of sensors in membranes to monitor health conditions or environmental changes in real-time.

- Eco-Friendly Materials: Development of sustainable rubber compositions that reduce environmental impact while maintaining performance.

- Customizable Solutions: Tailored membranes designed based on specific industry needs, allowing for more efficient and effective applications.

Challenges and Solutions in Implementation

Despite the numerous benefits, the implementation of multi-layer rubber membranes can pose challenges, including:

- Manufacturing Complexity: Producing multi-layer membranes requires advanced technology and expertise.

- Cost of Materials: Premium materials can drive up initial costs, posing a barrier for smaller businesses.

However, these challenges can be mitigated through:

- Partnerships with Suppliers: Collaborating with specialized suppliers can ensure high-quality production.

- Investment in Technology: Investing in modern production methods significantly enhances efficiency and reduces waste.

- Training Staff: Providing your team with the necessary training on handling and utilizing these materials effectively.

Conclusion: The Future of Multi-Layer Rubber Membranes

In conclusion, multi-layer rubber membranes are revolutionizing various industries by offering enhanced durability, versatility, and health benefits. Their continued evolution signals a promising future where they will become integral to health, beauty, and medical applications. As businesses adapt to the advancements in membrane technology, they stand to gain a competitive edge by integrating these high-performance materials into their products and services. Embracing these innovations will not only improve operational efficiency but also contribute to a healthier bottom line.